| Name: | 120G frequency modulation radar level meter |

|---|---|

| Measuring medium: | liquid |

| Measuring range: | 0.05m~30m |

| Process connection: | G2A/1½ thread or flange ≥DN65 |

| Working temp: | -40~110℃ |

| Working pressure: | -0.1~1.6MPa |

| Accuracy: | ±2mm |

| Frequency range: | 123GHz |

| Output: | 4~20mA/HART/RS485 Modbus |

| Explosion-proof: | Exia ⅡC T6 Ga / Exd IIC T6 Gb |

Measuring medium: liquid

Measuring range: 0.05m~30m

Process connection: G2 A thread/flange ≥DN65

Process temperature: -40~110℃

Process pressure: -0.1~1.6MPa

Accuracy: ±2mm

Protection level: IP67

Frequency range: 123GHz

Power supply: two-wire (DC24V)/four-wire (DC12V~24V)/four-wire (AC220V)

Explosion-proof grade: Exia ⅡC T6 Ga / Exd IIC T6 Gb

Housing: Aluminum/Plastic/Stainless Steel

Signal output: 4~20mA/HART/RS485 Modbus

| Process connection | Flange/Thread | |||

| Material | SS304、PP | |||

| Shell | Seal | Silicone Rubber | ||

| Shell window | Polycarbonate | |||

| Ground terminal | Stainless steel | |||

| Power supply | 4-wire | Standard | (12~24)V DC | |

| Power consumption | max 80mA DC24V/2W | |||

| Allow ripple | <100Hz | Uss<1V | ||

| (100~100K)Hz | Uss<10mV | |||

| Double chamber shell | (198~242)V AC | 4-wire | ||

| 100V AC | 4-wire | |||

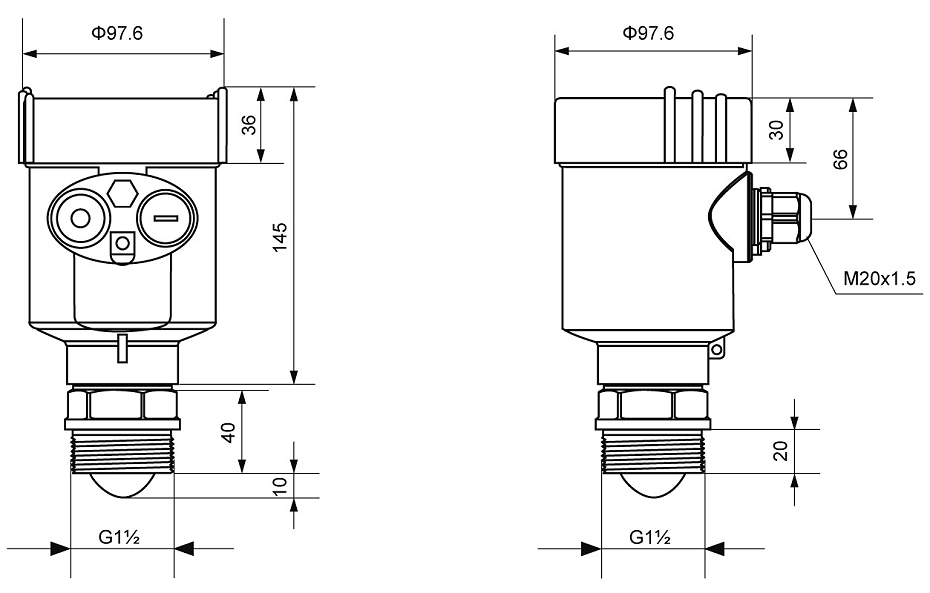

| Cable | Cable entry/plug | M20x1.5 cable entry | ||

| Blindness M20×15 | ||||

| Ground terminal | Conductor cross-sectional area 2.5mm2 | |||

| Output parameters | Signal output | 4~20mA/RS485Modbus | ||

| Resolution | 1mm | |||

| Fault signal | Current output unchanged; 20.5mA; 22mA; 3.9mA | |||

| Integration time | (0~20)s, adjustable | |||

| Blind spot | 0.1m/0.2m/0.3m | |||

| Maximum measurement interval | 150m | |||

| Measuring distance | About1s (Depending on parameter settings) | |||

| Adjust time | About1s (Depending on parameter settings) | |||

| Working, storage and transportation temperature | -40~80℃ | |||

| Process temperature | HBRD-FMF11 | -40~80℃ | ||

| HBRD-FMF12 | -40~110℃ | |||

| HBRD-FMF13 | -40~110℃ | |||

| HBRD-FMF15 | -40~200℃ | |||

| HBRD-FMF21 | -40~110℃ | |||

| Relative humidity | <95% | |||

| Working pressure | Max 2.5MPa | |||

| Shockproof | Mechanical vibration 10m/s2, (10~150)Hz | |||

● Millimeter-wave radar, with a measurement accuracy of up to ±2mm, and a minimum blind area of 0.05m.

● The smaller antenna size satisfies the measurement of more working conditions.

● A variety of lens antennas, smaller launch angle, more concentrated energy, stronger echo signal, and higher reliability than other radar products under the same working conditions.

● With stronger penetrability, it can be used normally even if there is adhesion and condensation.

● The dynamic model has a larger range, and the measurement of low dielectric constant medium is more stable.

● Multiple measurement modes, the radar response time in fast measurement mode is less than 1s.

HBRD-FMF series sensor is a 120G frequency modulation radar type level measuring instrument with a measuring distance of up to 30 meters. The antenna is further optimized, and the new and fast microprocessor can perform higher-speed signal analysis and processing, so that the meter can be used for measuring high temperature and high pressure and other environmental liquids.

The general principle of the FM continuous wave radar level gauge is that the radar emits electromagnetic waves on the top of the tank, and the electromagnetic waves are received by the radar after being reflected by the medium. The frequency difference δ f between the received signal and the transmitted signal is proportional to the distance R from the surface of the medium. : R= C (speed) *δ f (frequency difference) /2/K (frequency modulation slope). Because the speed of light C and the frequency modulation slope K are known, the frequency difference δ f can be estimated to obtain the distance R of the material surface at the radar installation position, and then through the known total height of the tank, subtract the spatial distance from the radar to the material surface ( Referred to as the air height) to get the height of the material level.

The radar level gauge is a continuous level measurement instrument. It is an advanced measuring instrument, suitable for solid materials, process containers, or strong dust that is easy to crystallize and dew. It has the advantages of low maintenance, high performance, high precision, high reliability and long service life. It can adapt to harsh production environments such as high temperature, high pressure and steam. The non-contact measurement method. Because it does not contact the measured medium, the radar level gauge is almost maintenance-free, free from damage, hanging materials, etc., no replacement of parts, long life, simple installation, simple calibration, and no material The influence of gas composition, dust, and temperature changes in the warehouse.

Radar level gauge has the characteristics of being not affected by the specific gravity of the medium, not affected by the change of the dielectric constant, and does not require on-site calibration. It has the advantages of accurate measurement, stable performance, high reliability, easy maintenance, and wide application range, so it can be used In many industries, power industry, steel industry, metallurgical industry, cement industry, petrochemical industry, paper industry, food industry, etc., as well as the occasions where dust, temperature, pressure change, inert gas and steam exist Level measurement of liquids, slurries and granular liquids in metal and non-metal containers or pipelines. In the process of industrial production, the radar level gauge can monitor the use of the liquid in the designated storage tank in real time, which is convenient for the on-site staff to observe.